Have you ever looked at your espresso and wondered how it got there? There’s a long story behind every cup of coffee, long before it reaches you – it passes through many hands and machines. Coffee is produced from different countries and in many ways. Today, let’s imagine the story of one shot of espresso from Guatemala.

Coffee Plants

In a valley surrounded by volcanoes, under the shadow of grevilea trees, fields of Arabica coffee are growing. They usually take 3 – 5 years to grow, and have 3 main varieties; Caturra, Catuai, and Heirloom Bourbon. In the fields are coffee plants, they usually resemble shrubs or trees, and stand anywhere between 5 – 8 feet tall. The coffee plants are usually covered by shiny green leaves, with branches hanging in various heights. Along each branch, bright red coffee cherries can be seen bunched up together.

A bunch of bright red coffee cherries

The Coffee Harvest!

Coffee fields are usually ripe for harvest between December and March. Each field is cared for by farmers who grow and harvest coffee plants by hand. Many farmers hand pick fruits that are ripe, and will visit each field up to 6 times throughout harvest season. Others will strip the plant of its coffee cherries in one go – whether it’s green or ripe. From a quality point of view, your espresso will taste a lot better if it just uses ripened coffee beans than either green beans or a mix.

Freshly Picked Coffee Cherries

De-pulping: Removing the Coffee Fruit

So after the harvest, there are farmers who will process the coffee themselves, and they will bring their coffee fruit back home. Others will bring their coffee cherries to the closest village and sell them to a middleman, who collects and sells them on to larger coffee plantations.

From here, the process of producing coffee diverges between smaller producers and large plantations.

Normally, those who produce their own coffee beans will own a small, motorized pulping machine. Some will even have a custom pulping machine powered by a re-purposed bicycle. The farmers here will only process coffee cherries that’s been hand-picked, and pre-filtered by them.

Pulping is the process of removing the fruit skin from the coffee bean.

Ideally, the coffee fruits should be pulped each day after the harvest. They should not be left alone for too long without pulping because it may affect the fermentation process and could cause everything to spoil from the get-go.

As for large plantations, they usually receive their coffee fruits late in the evening from small farmers and their own harvests. The fruit is batched together and pulped in large, industrial sized wet-processing pulping machines. These machines can typically process over a thousand pounds of coffee per day.

Normally, coffee cherries are stored in a receiving tank and are pushed by water to a pulping machine. Whilst flowing to the machine, dried cherries tend to stay afloat and removed. When the fruit enters the machine, it will be pushed against a few rotating rollers. During this process, under ripe cherries (or green cherries) are separated. The coffee fruits fall out at the bottom of the machine, and the coffee beans are washed out through a chute in the front of the machine. Both local farmers and plantations usually return the coffee fruits to the field as a form of organic compost.

Although processes are set in place to remove cherries that are dried or under ripe, some plantations will have difficulty monitoring the quality of the coffee beans coming out (due to quantity), and ensuring that they are all processed on the same day the fruits are picked.

VIDEO: Wet Process Coffee in Guatemala

To explain how coffee pulping works, I’ve found a video that goes through this in more detail – check it out.

Coffee Fermentation

The process of fermentation is basically a microbiological reaction where yeast and bacteria break down the sugar in the beans. There are coffee producers who skip this step in other countries, but in Guatemala, it’s an important process in coffee production. It is important to control the level of fermentation because experts found if coffee beans are over-fermented, it will affect the bean’s principle flavor, and will give off an unpleasant alcohol-like tones along with other less desirable flavors.

Over-fermented coffee beans are often a result of poor control in all processes so far; harvesting, pulping, and fermentation itself. If the coffee cherries are harvested at a different level of ripeness, then some coffee beans will ferment quicker than others. In addition, coffee producers have noticed fruits that aren’t pulped within 6 hours after harvest will typically have a higher chance of having problems when it’s fermented.

Small Producers

Fermentation is quite simple. After pulping, the slimy beans are put in plastic sacks and tied shut. The coffee sacks are then left alone on a patio outside the farmer’s home, and the fermentation process will occur naturally. This process usually takes around 24 – 36 hours depending on weather conditions. If it’s warmer and sunnier, then the fermentation time will be shorter. The farmers usually check the coffee beans after 24 hours and every 30 minutes after that. Based on the kind of sound and stickiness of the beans, the farmers can tell when to stop the fermentation process.

Fermenting coffee by the patio

Large Plantations

After pulping process, the coffee beans are poured into a large cement fermentation tank. Sometimes water is used and the beans are left underwater. Overall, both smaller farmers and larger plantations use similar tactics. The coffee beans are checked every so often after 24 hours to determine how the fermentation process is progressing. Once the coffee beans are fermented, it’s time to move on to the next step.

Washing the Coffee Beans…

The next step of the process is washing, where the stickiness and slime on the coffee beans are washed away. In this process, there’s literally no difference between small producers and industrial sized plantation. The only different is in scale. As you might expect, plantations will use more complex machinery and washing methods, whilst small producers tend to use something simple, like a basket or tub of water for washing process.

Washing coffee in a tub – local producer

Coffee Process – Drying the Beans

After washing…comes drying… The warm weather of Guatemala usually means that coffee beans usually take around 8 – 12 days to dry.

Coffee beans are usually spread out and dried on patios. In many smaller farmers’ homes, space is scarce, so they will lay the coffee beans on their roof instead. Although the farmers are precautious, their children usually climb up to the roof and stir the coffee beans each day. As for coffee plantations, they usually use small tractors with special adjustments to stir their beans.

Stirring is a crucial step in-order to achieve evenly dried coffee beans.

Although the harvest season happens on the same time as the dry season, the occasional rainstorm sends farmers and coffee processors into a flurry to cover coffee that’s in the process of drying. When this happens, the coffee is quickly pushed together in mounds and covered with large sheets of plastic.

Whilst some use special coffee-moisture detectors to measure the moisture percentage in the bean, a more common practice is simply bite the bean to test its dryness. The sweet spot is usually a bit between pasta’s al-dente and hard as rock. Ideally, the beans should contain around 9-11% moisture content. Anything more and they may be vulnerable to mold growth. If the moisture content is less, there will be less flavor and more difficult for roasters to handle.

Coffee Hulling

Hulling is the removal of the paper-like outer layer that is still attached to the bean after drying. This is usually done by using a motorized machine. Similarly to the pulping machine, the coffee beans are rubbed on the huller, which breaks the brittle outer layer. The remaining outer shell is then blown away.

Hulling is the removal of the paper-like outer layer that is still attached to the bean after drying.

Coffee beans before hulling are known as ‘parchment coffee’, where a paper shell is formed during the drying stage. It’s yellowish and quite brittle, but it’s there to protect the bean from dust and humidity.

This outer shell must be removed before exporting. In this process, the bean’s moisture content will sometimes drop because of the heat caused by friction when the shell is being removed. All producers are aware of this and usually takes this to a count in the drying stage in-order to export the coffee beans in optimal conditions.

Once the hulling process is complete, the coffee beans will become what’s known as ‘green beans’, because of its emerald green color. In Guatemala, green beans are also known as ‘café oro’, which means gold coffee. This is due to the value that processed coffee beans commands over coffee fruit.

“Café oro” means gold coffee in Guatemala

Classification

There are 2 main stages in this process and is usually very labor intensive. In the 1st stage, the coffee beans are passed through a screen filter. The screen filter is used to filter the larger beans by allowing smaller and broken ones to fall through. The beans that remain will be classified based on sizing charts. This is very important in the roasting stage because smaller beans will roast quicker than larger beans, which in turn, produces an uneven roast.

The 2nd stage is picking out defects by hand, defects such as discolored beans, broken beans, or misshaped beans. These defects will produce uncontrolled flavors, which typically affects the roasting negatively.

In most cases, these labor intensive tasks are done by women. Small farmers and plantations alike hire extra workers to classify the coffee. Often, children play around and under the table whilst their mother pick through each bean individually.

Export

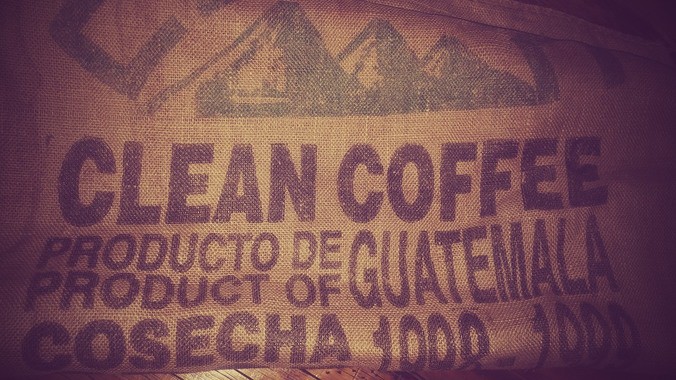

Exporting – This part is not the least interesting. The coffee beans are packed in burlap sacks, put in a shipping container, where it’s transported to a shipping dock, and finally, begins its journey to other parts of the world.

Coffee burlap sack ready for export

Roasting

From this point onwards, most of you will know the rest.

Roasted coffee in my local market

(Guatemalan beans on the top right)

In this process, the wonderful aroma of coffee is produced. The coffee beans are heated up through roasting, turning the beans from green to brown. There are many different ways to roast the coffee beans. These methods will give the beans different shades and flavors. Coffee roasting is a precise art.

The majority of time, green coffee is roasted by industrial roasters, but some artisan coffee shops may also roast their own. Roasting machines run in different capacities, from something as small as 5lb to 100lbs upwards. Coffee roasting businesses often use smaller machines to ‘test roast’ new batches of green beans before proceeding to larger roasters for larger quantities. The most common type of roasters is the drum roaster, where the beans are put in a turning barrel over gas or wood flame.

Coffee roasters normally determine when to complete the roast based on factors such as sound, time and temperature. Coffee beans normally make a distinctive cracking sound when water vapor is released and when they reach a certain temperature. During the roasting session, there could be 2 cracks. The 1st crack indicates that a lighter roast is reached, whilst the 2nd crack is heard when the coffee bean reaches a darker roast. Most coffee roasters will usually come with a small trap door because roasters will typically look for clues such as color, presence of oil, and taste, when achieving the desired roast.

Overall, from this point forward, it’s best to use the coffee beans up in 2 weeks, and potentially 1 month if refrigerated.

Grinding and Brewing

The final step is grinding and brewing the coffee. For a cup of espresso, it’s best to grind your coffee beans just before it’s brewed. Once grounded, they usually start to lose its quality after a few minutes. In terms of an espresso, a quality grinder is needed to produce fine and even grinds. Click here to see the best coffee grinders.

As for brewing, you’re probably all familiar with it already. Water quality, temperature, and pressure are all factors that affect how well your espresso will taste. Lastly, after brewing, the sooner it’s consumed the better.

Grounded up coffee

Now that you’ve learned all the steps it takes to produce a cup of espresso, I hope you’ll be in awe next time you take a sip. Imagine how long and difficult it is for each bean to be handpicked, processed, and classified before they even reach the roaster. It’s a very labor-intensive process indeed. Now that you know the story of your coffee’s journey, next time you might just be able to taste a hint of Guatemalan sun as you enjoy your espresso.